Unleashing Precision and Excellence with Custom CNC Machining Service in Metal Fabrication

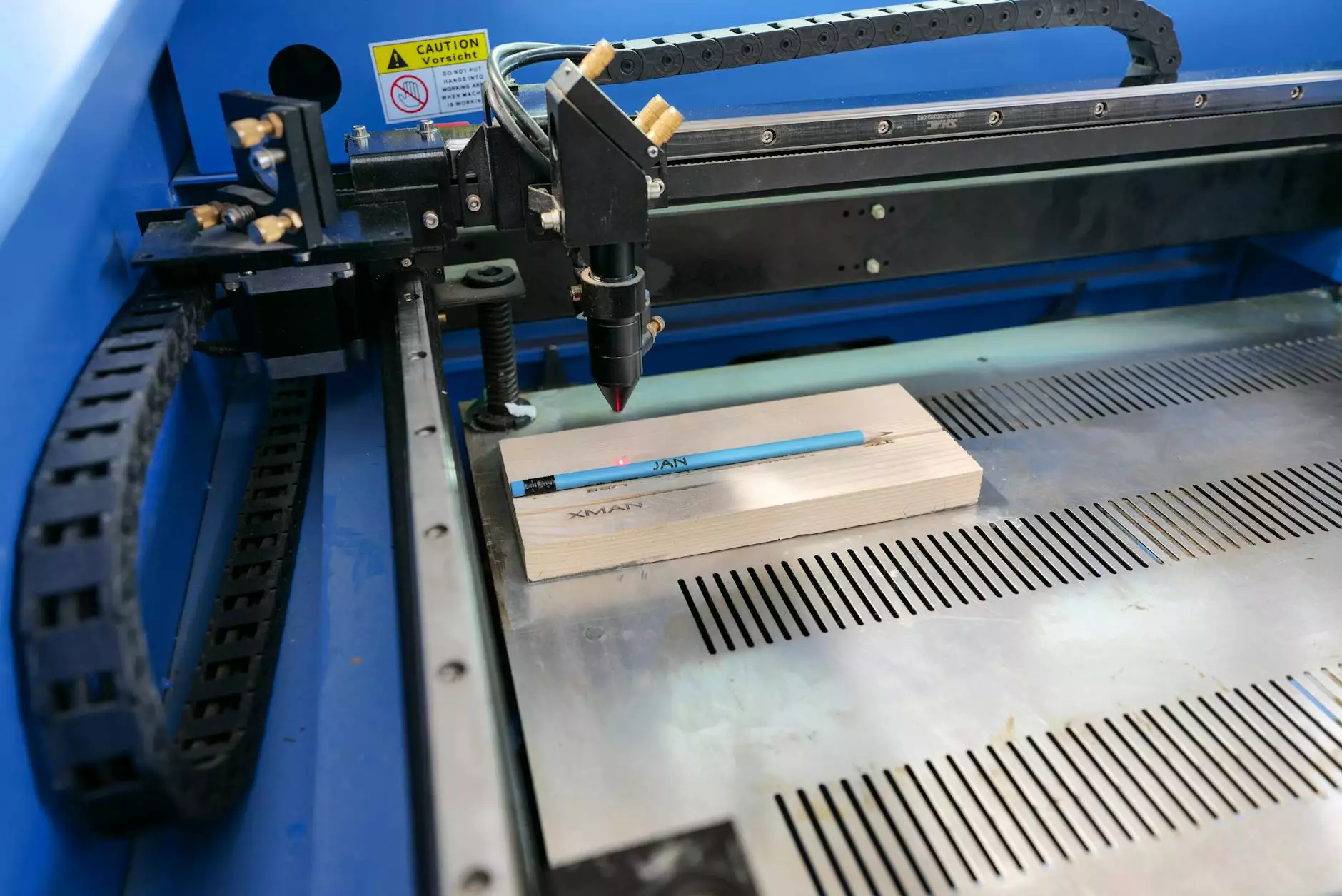

In today’s highly competitive manufacturing landscape, businesses demand not only high-quality products but also efficient and reliable fabrication processes. Custom CNC machining service has become the backbone of modern metal fabrication, enabling manufacturers to produce complex, precise components at scale. At DeepMould, we pride ourselves on delivering industry-leading custom CNC machining solutions designed to meet the specific needs of our clients across diverse sectors.

Understanding the Significance of Custom CNC Machining Service in Metal Fabrication

Computer Numerical Control (CNC) machining revolutionized the manufacturing industry by offering unmatched accuracy and repeatability. The custom CNC machining service elevates this technology by tailoring the machining parameters to exact specifications, ensuring every part completed meets the highest standards of quality. This level of precision is critical in sectors such as aerospace, automotive, medical devices, electronics, and industrial machinery, where tolerances are tight, and component integrity is paramount.

Key Advantages of Choosing Our Custom CNC Machining Service

- Exceptional Precision & Accuracy: Our advanced CNC equipment ensures parts are machined to exact tolerances, often within microns.

- Complex Geometries & Custom Designs: Capable of manufacturing intricate and complex shapes that traditional methods struggle with.

- Rapid Prototyping & Short Lead Times: Accelerate your product development cycle with quick turnaround times.

- Consistency & Repeatability: Maintain identical quality across large production runs, reducing waste and rework.

- Cost-Effective Solutions: Minimize material waste and labor costs without compromising quality.

Why DeepMould Stands Out as a Leading Custom CNC Machining Service Provider

At DeepMould, our commitment to excellence, innovation, and customer satisfaction distinguishes us from other metal fabricators. We combine cutting-edge CNC machining technology with a team of skilled engineers and technicians to ensure every project is completed to perfection. Our integrated manufacturing processes allow us to handle a wide array of materials, including various metals such as Aluminum, Steel, Brass, Copper, Titanium, and exotic alloys.

State-of-the-Art Equipment and Technology

Equipped with the latest CNC mills, lathes, and multi-axis machines, we can produce complex parts with high precision. Our facilities incorporate advanced tooling, automation, and measurement systems to guarantee that each component meets strict specifications. This technological edge ensures that our custom CNC machining service remains at the forefront of the industry.

Dedicated Engineering and Design Support

Our expert engineering team collaborates closely with clients from the initial concept through to final production. We provide comprehensive design for manufacturability (DFM) analyses, helping optimize designs for CNC machining while reducing costs and lead times. This proactive approach ensures that your project benefits from maximum efficiency without sacrificing quality.

Quality Control and Certification

Quality assurance is central to our operation. Every batch of components undergoes rigorous inspection, including coordinate measuring machine (CMM) verification, surface finish assessments, and dimensional checks. Our adherence to industry standards such as ISO 9001 guarantees that your parts are manufactured under consistent quality protocols, making us a trusted custom CNC machining service partner.

Applications of Custom CNC Machining Service in Modern Industries

The versatility of our custom CNC machining service allows us to cater to a broad spectrum of industrial applications, providing tailored solutions that meet the specific demands of each sector.

1. Aerospace & Defense

Manufacturing aircraft components, missile casings, and precision instrument parts requires the highest level of accuracy and material integrity. CNC machining helps produce lightweight yet durable parts, reducing weight while maintaining structural strength.

2. Automotive Industry

From engine components to custom brackets and fixtures, automotive manufacturers rely on CNC machining for rapid prototyping and high-volume production, ensuring tight tolerances and excellent surface finishes.

3. Medical Devices & Dental Equipment

Precision is vital in the medical field. CNC-machined parts such as surgical instruments, implants, and dental prosthetics demand meticulous craftsmanship and biocompatible materials.

4. Electronics & Consumer Products

Custom enclosures, heatsinks, and intricate components are all produced efficiently through CNC machining, supporting cutting-edge electronic devices.

5. Industrial Machinery & Equipment

Custom machined parts enhance the performance of industrial tools, valves, and structural frames, improving durability and operational efficiency.

The Process of Engaging Our Custom CNC Machining Service

Partnering with DeepMould for your CNC machining needs involves a streamlined process designed to maximize efficiency and quality:

- Design & Consultation: Share your design files (CAD, STEP, IGES) and discuss project specifications with our engineering team.

- Feasibility Analysis & Quotation: We evaluate your design for manufacturability, providing detailed quotes and any suggestions for optimization.

- Prototype Development: Upon approval, we create prototypes to validate design and functionality.

- Production & Quality Assurance: After final approval, production commences with rigorous quality checks at every stage.

- Delivery & Support: We ensure timely delivery and are always available for post-production support or modifications.

Custom CNC Machining at DeepMould: Your Reliable Metal Fabricator Partner

Choosing the right custom CNC machining service partner is critical for the success of your project. DeepMould’s extensive experience, innovative technology, and dedicated customer service make us the ideal choice for businesses that require precision-engineered metal components. Our customizable solutions, fast turnaround times, and stringent quality controls ensure that your projects are completed to your exact specifications.

Enhance Your Manufacturing with Our Expert Custom CNC Machining Service

If you aim to elevate your product quality, reduce manufacturing costs, and achieve faster time-to-market, our custom CNC machining is the solution you need. We combine technological superiority with a customer-centric approach, ensuring every project fulfills your vision and exceeds your expectations.

Contact DeepMould Today for Unmatched CNC Machining Solutions

Ready to experience the highest standards in custom CNC machining service? Reach out to DeepMould today. Our team is committed to providing innovative, precise, and reliable metal fabrication solutions that empower your business to succeed in a competitive market.

DeepMould – Your Trusted Partner in Custom CNC Machining Service and Metal Fabrication Excellence.